References

268 Water Treatment Plants and 237 Fume Treatment Plants with high customer satisfaction rating

Acciaierie Venete S.p.A - FTP (2025)

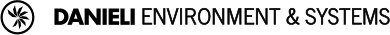

Fume Treatment Plant for the 130-ton Electric Arc Furnace and other auxiliary suction lines for the meltshop in Spain.

For Danieli the scope of the project foresees plant design, manufacturing, technological supply erection and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Three (3) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- Electrical and automation systems.

The FTP will treat approximately 2.2 Million m3/h.

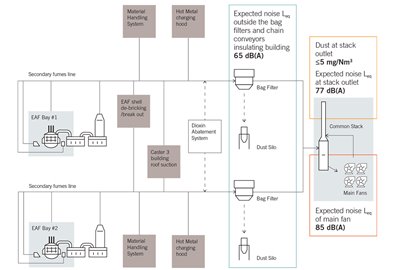

Acciaierie Venete S.p.A - FTP (2025)

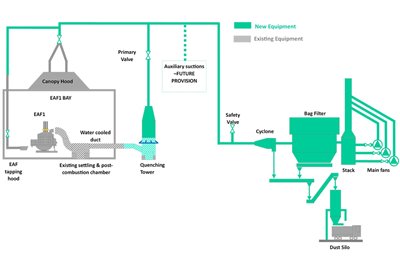

Fume Treatment Plant for the 93-ton Electric Arc Furnace and other auxiliary suction lines for a new meltshop in Italy.

For Danieli the scope of the project foresees plant design, manufacturing, technological supply erection and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Two (2) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- A Dioxin Abatement system

- Electrical and automation systems.

The FTP will treat approximately 1.1 Million m3/h.

Gerdau S.A. Pindamonhangaba - FTP (2024)

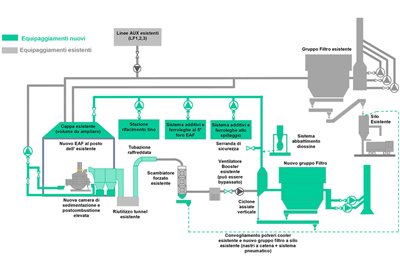

Fume Treatment Plant for the 110-ton Electric Arc Furnace and other auxiliary suction lines for a new meltshop in Brazil.

For Danieli the scope of the project foresees plant design of the FTP comprised of:

- A Pulse Jet Filter

- Three (3) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- Quenching Tower

- Electrical and automation systems.

The FTP will treat approximately 1.6 Million m3/h.

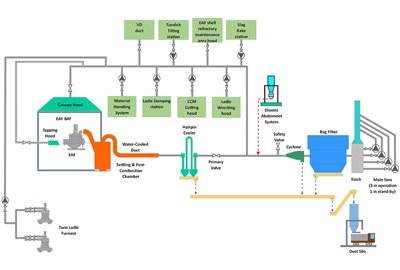

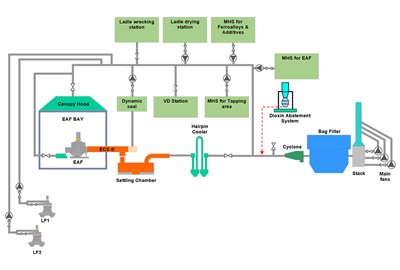

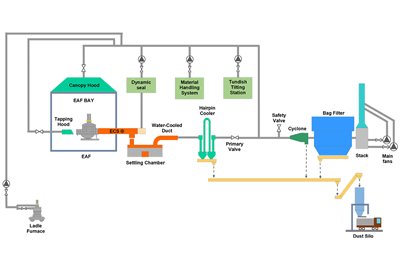

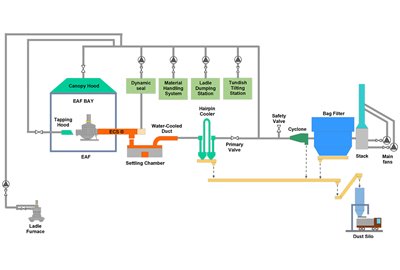

ArcelorMittal Tubular Products Al-Jubail - FTP (2024)

Fume Treatment Plant for the 120-ton Electric Arc Furnace and other auxiliary suction lines for a new meltshop in Kingdom of Saudi Arabia.

For Danieli the scope of the project foresees plant design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Four (4) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- A Hairpin Cooler

- A Dioxin Abatement system

- Electrical and automation systems

The FTP will treat approximately 2.2 Million m3/h.

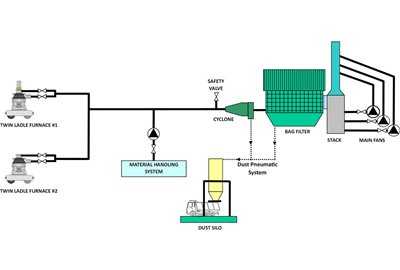

ArcelorMittal Tubarão - FTP (2024)

Fume Treatment Plant for the 315-ton Twin Ladle Furnace and other auxiliary suction lines for the meltshop in Brazil.

For Danieli the scope of the project foresees plant design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Three (3) ID fans with variable-frequency drives

- Electrical and automation systems.

The FTP will treat approximately 0.5 Million m3/h.

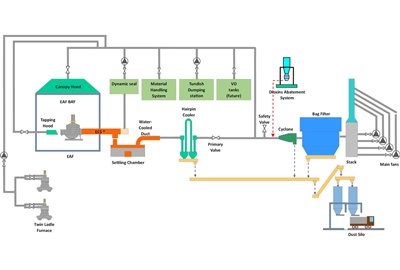

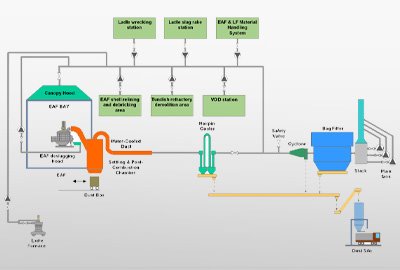

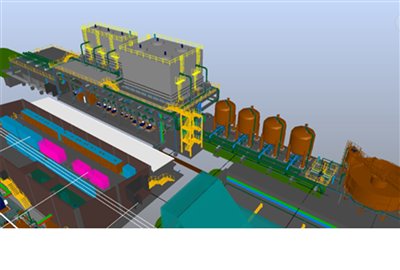

Kroman Celik Sanayii A.S. - FTP (2023)

Fume Treatment Plant for the 150-ton Electric Arc Furnace and other auxiliary suction lines for a new meltshop in Turkey.

For Danieli the scope of the project foresees plant design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Four (4) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- A Hairpin Cooler

- A Dioxin Abatement system

- Electrical and automation systems

The FTP will treat approximately 2.4 Million m3/h.

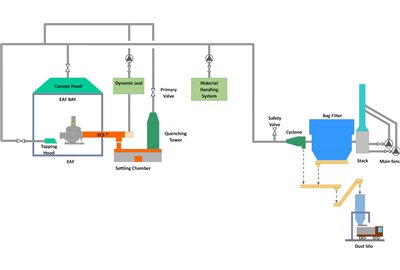

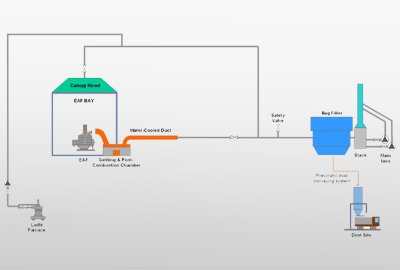

New Zealand Steel Limited - FTP (2023)

Fume Treatment Plant for the 80-ton Electric Arc Furnace and other auxiliary suction lines for a new meltshop in New Zealand.

For Danieli the scope of the project foresees plant design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Two (2) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- Quenching Tower

- Electrical and automation systems

The FTP will treat approximately 1.3 Million m3/h.

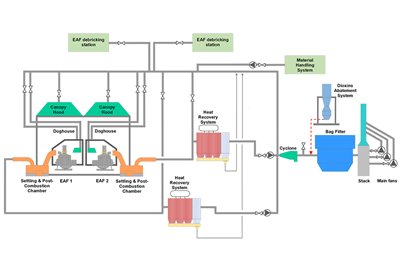

Voestalpine Stahl Donawitz GMBH, Austria - FTP (2023)

For Danieli the scope of each project foresees plant design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Three (3) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- Two (2) DogHouse

- Two (2) Heat Recovery System

- Dioxin Abatment System

- Electrical and automation systems.

The FTP will treat approximately 2.4 Million m3/h.

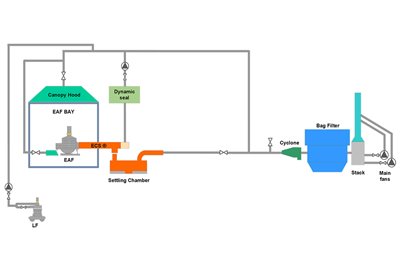

Whyalla Steelworks, Australia - FTP (2023)

For Danieli the scope of each project foresees plant design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Three (3) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- A Hairpin Cooler

- Dioxin Abatment System

- Electrical and automation systems

The FTP will treat approximately 2.3 Million m3/h.

Sidersa SA, Argentina - FTP (2023)

For Danieli the scope of each project foresees plant design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Two (2) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- Electrical and automation systems

The FTP will treat approximately 1.1 Million m3/h.

CMC Steel Tennessee, USA - FTP (2023)

For Danieli the scope of each project foresees plant design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Two (2) ID fans with variable-frequency drives

- Water-cooled ducts

- Electrical and automation systems

The FTP will treat approximately 1.3 Million m3/h.

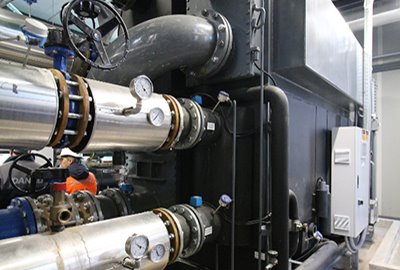

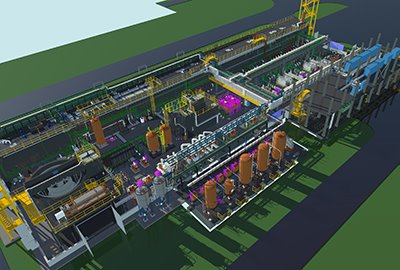

Salcos Salzgitter, Germany – WTP (2023)

The Danieli scope of supply will be the full water treatment plant system which is the most critical and fundamental auxiliary plant for the direct reduction plant, together with the Natural Gas Station.

The WTP is composed by three different cooling circuits:

- QW closed circuits (1,035 mc/h)

- CW/QCW non-contact circuits (9,217 mc/h)

- KW contact circuits (1,052 mc/h)

Danieli Engineering met the two main client requirements: adjusting the plant inside a limited footprint area (considering we are inside a brown filed case) and reducing the water consumption of approx. 60% using air coolers instead off cooling towers for non-contact circuits. The WTP is complete of a detailed uptake network to collect and treat the air removing the ammonia complying with local norms.

The automation system is in common with the one of DRP as WTP is part of DRP process.

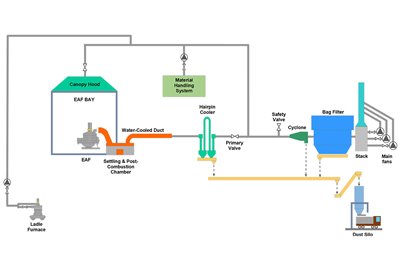

Middle East - FTP (2022)

For Danieli the scope of each project foresees plant design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Two (2) ID fans

- Water-cooled parts (ducts and settling chamber)

- A Hairpin Cooler

- Electrical and automation systems

The FTP will treat approximately 1.4 Million m3/h

Middle East - FTP (2022)

For Danieli, the scope of the project foresees plant design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Three (3) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- A hairpin cooler

- Electrical and automation systems.

Meghna Group of Industries, Bangladesh - FTP (2022)

For Danieli the scope of each project foresees plant design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- One (1) Pulse Jet Filter

- Three (3) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- A Hairpin Cooler

- Electrical and automation systems.

The FTP will treat approximately 2.3 Million m3/h.

Liberty Ostrava, Czech Republic - FTP (2022)

For Danieli the scope of each project foresees plant design, manufacturing, supply and advisory services of the FTP, comprised of:

- Two (2) Pulse Jet Filter

- Four (4) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- Two (2) Quenching Tower

- Electrical and automation systems

The FTP will treat approximately 3.8 Million m3/h.

Unitex, Bangladesh - FTP (2022)

For Danieli the scope of each project foresees plant design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Two (2) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- A Hairpin Cooler

- Electrical and automation systems.

The FTP will treat approximately 1.4 Million m3/h.

Scaw Metal, South Africa – WTP (2022)

DESY department design and supply a high technological Water Treatment Plant for the new Narrow Hot Strip Mill. The WTP is characterized by the most updated technology develop by Danieli for the steel sector, including Q-water for power saving and the DCWC (Danieli Cooling Water Cascade) for reducing circulating water flow:

- Indirect cooling circuit (2.550 mc/h)

- Direct cooling circuit (4.630 mc/h)

- Make up water (90 mc/h)

Our team met the client requirements, reusing the existing, scale pit, saving cost for the client, and time for the project.

The Danieli-patented DanFilters technology, contribute to design a compact lay out The automation system is integrated to create a single unit NHSM & WTP.

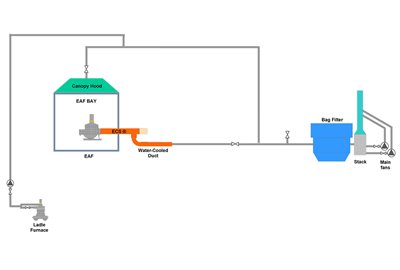

Nucor Cavalier, USA - FTP (2022)

For Danieli, the scope of the project foresees design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Two (2) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- Electrical and automation systems.

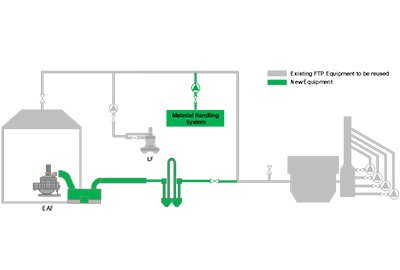

ArcelorMittal Barra Mansa , Brasil – WTP for a Section Mill (2022)

The client bought a new Danieli Section Mill in a place of and old one and need to install a new WTP too, client ask to save the existing civil part as mush as was possible.

We apply the most updated technology develop by Danieli for the steel sector:

Zero Scale Pit: reduce the excavation and civil works for the scale pit and make easy the scale removal

DanFilters: applying our sand filters we reduce the number of filters from 4 to 3.

With our technology we reuse:

- Settling pond

- Backwash water settling tank

- Control room

- One concrete cooling tower

- Pump room

- Sand filters main foundation

Main data are:

- Indirect cooling circuit (800 mc/h)

- Direct cooling circuit (1000 mc/h)

- Make up water (25 mc/h)

The big saving for the civil construction was the driving force to award the contract.

Pacific Steel Ltd., USA - FTP (2022)

For Danieli the scope of each project foresees plant design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Two (2) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- Electrical and automation systems.

ESF ELBE - Stahlwerke Feralpi, Germany – WTP for a bar and wire rod Mill (2022)

The plant is designed to treat and recycle all the contact and not contact water coming from of mill and reheating furnace, finishing part.

The WTP is characterized by the most updated technology develop by Danieli for the steel sector:

- Zero Scale Pit: reduce the excavation and civil works for the scale pit and make easy the scale removal

- DanFilters: the patented highspeed sand filters designed in our research center reducing the footprint.

Main data are:

- Indirect cooling circuit (1,010 mc/h)

- Direct cooling circuit (1620 mc/h)

- Make up water (43 mc/h)

Chiyoda Steel Corporation, Japan – WTP for a MIDA (2022)

Chiyoda Steel decided to install a MIDA on an existing building, they need a new WTP to serve the MIDA but have a small area available to use. Danieli was able thanks to his technology to cover the MIDA request with some smart solutions. Again the Danfilters where important to reduce the footprint.

Main data are:

- Indirect cooling circuit (1230 mc/h)

- Direct cooling circuit (1100 mc/h)

- Make up water (65 mc/h)

The big saving for the civil construction was the driving force to award the contract.

Alexey Ugarov OEMK, Russia- FTP (2021)

The project foresees the design, manufacture, technological supply and advisory services of the new primary line, consisting of water-cooled parts, quenching tower and electrical and automation systems.

The new primary line will treat approximately 215,000 Nm3/h.

Algoma Steel Inc., CANADA - FTP (2021)

For Danieli the scope of the project foresees plant design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Three (3) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- A quenching tower

- Doghouse fume collection structure

- Dioxin abatement system

- Electrical and automation systems.

Format-EK, LLC, RUSSIA - FTP (2021)

For Danieli the scope of the project foresees design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Two (2) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- A Quenching Tower

- Electrical and automation systems.

Al Ezz Flat Steel, Egypt - FTP (2021)

For Danieli the scope of the project foresees design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Three (3) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- A hairpin cooler

- Electrical and automation systems.

The FTP will treat approximately 2.5 Million m3/h.

AO Steel Works Balakovo, Russia- FTP (2021)

Danieli's project includes the design, manufacture, supply and advisory services for the complete FTP, comprised of:

- A Pulse Jet Filter

- Four (4) ID fans with variable-frequency drives

- All water-cooled components, with a completely water-cooled settling chamber

- Quenching tower

- Dust conveying system and pelletizer

- Electrical and automation systems.

The FTP will treat approximately 3.0 Million m3/h.

Bashundhara Multi Steel Industries Ltd., Bangladesh – FTP (2020)

For Danieli the scope of this project includes design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter

- Two (2) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- A hairpin cooler

- Electrical and automation systems.

The FTP will treat approximately 1.4 Million m3/h.

PJSC Magnitogorsk Iron and Steel Works (MMK), Russia – FTP (2020)

Danieli's project consists of plant design, manufacture, supply and advisory services for the complete FTP for EAF #1 and primary line for EAF #2 ,where the existing bag filters have been recovered. The installation is comprised of:

- Pulse Jet Filter

- Four (4) ID fans with variable-frequency drives

- All water-cooled ducts and settling chamber panels for both EAFs

- Quenching tower system

- Dust conveying system

- Electrical and automation systems.

The FTP will treat almost 2.4 Million m3/h.

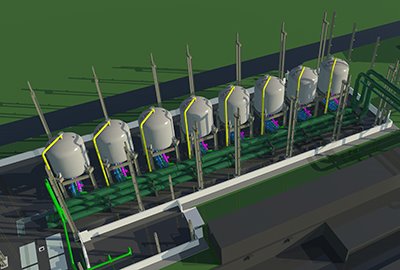

JSC VSW Vyksa Steel Works, Russian Federation – WTP for DRP (2020)

The Danieli supply included process cooling circuits for make- up and blow-down water

- Indirect cooling circuit (11,900 mc/h);

- Direct cooling circuit (1030 mc/h);

- Make-up water (600 mc/h);

- Zero Liquid Discharge (blow-down water recovery) (180 mc/h);

Danieli Environment together with Danieli Plant Engineering developed a common project for a Direct Reduction Plant unit, using the Best Available Technology.

A part the cooling section the project includes a filtration battery made of six 3.8-m diameter DanFilters, with new design that includes the steel support.

A package of ammonia stripping is included, as well as for the make-up treatment of river water.

A Danieli Zero Liquid Discharge unit to recover the cooling towers' blow-down water completes a very up-to-date design.

JSC VSW Vyksa Steel Works, Russian Federation – WTP for SMP (2020)

The Danieli Supply included process cooling circuits, make-up and blow-down

- Indirect cooling circuit (15,040 mc/h);

- Direct cooling circuit (700 mc/h);

- Make-up water (325 mc/h);

- Zero Liquid Discharge (blow-down water recovery) (105 mc/h);

Danieli Environment met the client requirements to design a very compact plant, including all accessories, like sludge thickener and sludge centrifuge.

The project includes seven 3.8-m diameter DanFilters, with a new design that includes the steel support.

Make-up treatment of river water is part of the supply, to attain high water quality to increase the concentration factor in the cooling towers.

As for the previous projects, OMK confirmed its green steel commitment by installing a Danieli Zero Liquid Discharge unit to recover blow-down from the cooling towers.

Evraz Palmer North America, USA – WTP for Rail Mill (2020)

The plant is designed to treat and recycle all the contact and non-contact water coming from the mill and reheating furnace finishing part.

The WTP is characterized by the most up-to-date technology developed by Danieli for the steel sector, including:

> Zero Scale Pit, to reduce the excavation and civil works for the scale pit and simplify scale removal

> DanFilters, the patented, high-speed sand filters designed in our research center to reduce the footprint.

> Zero Liquid Discharge, a blow-down water treatment that recovers 70% of discharged water, reducing the amount of make-up water drawn from natural sources.

Main data are:

Indirect cooling circuit (1,300 mc/h);

Direct cooling circuit (550 mc/h);

Zero Liquid Discharge (blow-down water recovery, 20 mc/h).

The project combines highly efficient treatment with green technology within the water treatment system, recycling the backwash water from the sand filters.

The PLCs for the WTP and RM will be connected as a single system working together, making it possible to control the WTP from the pulpit of RM.

Danieli has confirmed its performance for designing and delivering tailored solutions with the best CapEx and OpEx, matching the requirements of each project.

Aceros De Guatemala, Guatemala – WTP (2020)

The Danieli Supply improves the direct cooling circuits.

> Direct cooling circuit (1,870 mc/h);

The plant is designed to treat and recycle all the contact water coming from of mill and quenching system.

The updated Water Treatment Plant will incorporate DanFilters, the patented high-speed sand filters designed in our research center. Thanks to DanFilters the footprint was reduced and the new required area is minimized.

All the existing concrete basins will be recovered, including scale pit and longitudinal clarifiers. Only one new pit will be necessary to handle the additional flowrate coming from the new heat treatment.

All new equipment will be from the same high-quality OEM, thus simplifying maintenance activities and spare parts management.

The old PLC will be recovered and connected to the new one that will handle the automation of both new and existing equipment. The signals also will be diverted to the RM pulpit to allow for remote control of the WTP.

Danieli, thanks to on-site survey and support, reconfirms its resources and know-how to design and provide tailored solutions with the best CapEx, including for WTP revamping.

ABS Acciaierie Bertoli Safau, Italy – WTP for CCM (2020)

Danieli Environment has designed and supplied a high-technological Water Treatment Plant for the new continuous casting machine installed at ABS.

The WTP is characterized by the most up-to-date technology developed by Danieli for the steel sector:

- Zero Scale Pit reduces the excavation and civil works for the scale pit and simplifies scale removal;

- DanFilters are the patented, high-speed sand filters designed in our research center, with a reduced footprint.

Main data are:- Indirect cooling circuit (2,330 mc/h);

- Direct cooling circuit (425 mc/h);

- Make-up water preparation with carboxylic IX resins (60 mc/h).

From order to commissioning it took us less than 12 months.

Nucor Steel Gallatin, USA - WTP (2019)

The Danieli supply included Casting and Rolling process cooling circuits.

- Indirect cooling circuit (26,870 mc/h);

- Direct cooling circuit (19,950 mc/h);

Thanks to Danieli-patented DanFilters technology, our project fit the area available for the installation of the new WTP equipment and saved 40% of space.

The automation system will be updated and integrated to create a single water treatment plant.

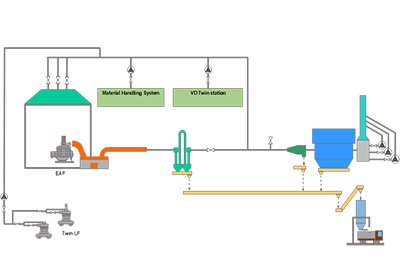

Nucor Steel Gallatin, USA - FTP (2019)

Fume Treatment Plant for the 170-ton Electric Arc Furnace, the Twin Ladle Furnace and other auxiliary suction lines of the new Meltshop expansion in Ghent, Kentucky (USA).

Danieli's project foresees the design, manufacture, supply and advisory services of the complete FTP, comprised of:- A Twin Reverse Air Baghouse, with a total surface of 90,585 m2

- Five (5) ID fans with variable frequency drives

- All water-cooled ducts and settling chamber panels

- A complete set of ducts and supporting structures

- A pneumatic Dust Conveying System

- A Dust Collecting System with a movable Dust Discharging System

- Electrical and Automation Systems.

The FTP will treat almost 3.6 Million m3/h, making this plant one of the largest Fume Treatment Plants sold by Danieli.

Nucor Steel Sedalia & Florida, USA (2019)

Danieli and the Nucor technical teams (Sedalia, MO, and Frostproof, FL) made a detailed evaluation of different process and plant configurations applicable to these specific cases; the final agreed technical solution and relevant advantages are listed below:

- Zero Scale Pit (screw type): this solution will save the cost of about 900 cm of civil construction and will avoid the usual large and deep underground pit needed to settle the scale. The Zero Scale Pit concept is based on simple, skid-mounted equipment with a screw to remove and collect the scale outside the plant

- Containerized electrical cabin: a ready-to-install electrical cabin reduces space requirements, civil design and works, cable length, installation time and commissioning period (about 3/4 weeks).

- DanFilter™: this Danieli-patented technology will reduce the plant layout by about 10%, with only three DanFilters of 3,800 mm diameter ensuring high-quality water circulation in all the production phases, minimizing production stoppages for maintenance and cleaning.

- Package cooling towers: easy and fast installation, as the equipment will arrive onsite partly preassembled, ready to connect.

- Integrated automation: Danieli Automation will integrate the WTP with the MIDA automation for Nucor operators' benefit.

North Star Bluescope Steel LLC, USA (2019)

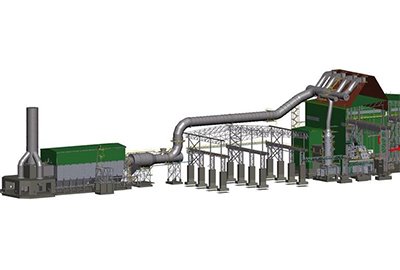

Fume Treatment Plant for the 177-ton Electric Arc Furnace and two Ladle Furnaces of the new Meltshop expansion in Delta, Ohio (USA).

The Danieli project foresees the design, manufacture, supply and advisory services for the complete FTP, comprised of:- A Pulse Jet Filter, with a total surface of 31644 m2

- Four (4) ID fans (3 working, 1 in standby)

- All water-cooled components, with a completely water-cooled settling chamber

- A stainless-steel Quenching Tower, with no refractory

- A complete set of ducts and supporting structures

- A pneumatic Dust Conveying System

- A Dust Collecting System with a movable Dust Discharging System

- Electrical and Automation Systems.

Uzmetkombinat JSC, Uzbekistan (2019)

For Danieli the scope of the project foresees design, manufacturing, technological supply and advisory services of the FTP, comprised of:

- A Pulse Jet Filter, with a total surface of 16200 m2

- Three (3) ID fans with variable-frequency drives

- Water-cooled parts (ducts and settling chamber)

- A Hairpin Cooler

- Electrical and Automation Systems.

PAO Severstal, Russia (2019)

The project foresees the design, manufacture, technological supply and advisory services of the new primary line, comprised of water-cooled parts, Hairpin Cooler and Electrical and Automation Systems.

The new primary line will treat approximately 230,000 Nm3/h.

Vyksa Steel Works, Russia (2019)

Danieli's project foresees the design, manufacture, supply and advisory services for the complete FTP, comprised of:

- A Pulse Jet Filter, with a total surface of 35151 m2

- Four (4) ID fans with variable-frequency drives

- All water-cooled components, with a completely water-cooled settling chamber

- Quenching Tower

- Dust Conveying System and Pelletizer

- Electrical and Automation Systems.

Acciaierie di Verona, Pittini Group (2018)

The design follows the client's requirements and local rules.

The following are the main advantages thermal recovery:- Simple and completely automatic machine;

- Low operating and maintenance costs;

- Environmentally sound solution - reducing CO2 emissions to the atmosphere;

- Energy saving solution

- Access to the green fiscal benefits

Toshkent Metallurgiya Zavodi, Uzbekistan (2018)

The new plant will be designed to purify and recycle all the polluted cold complex wastewaters using an advanced treatment method. The new Water Treatment Plant that will complete the supply of its Danieli cold mill complex

Algerian Qatari Steel, Algeria (2017)

Danieli provided a complete FTP including a pulse jet filter of 16.800 m2, a full water cooled settling chamber (elevated type), double Hairpin Cooler and suction lines provided for auxiliary.

The project has been managed as a complete turnkey project including design, manufacturing, erection, commissioning, shipments and management. With this project Danieli strengthened its presence in North Africa.

Tung Ho Steel, Vietnam (2016)

The supply includes backwash water of filtration and sludge treatment.

A very compact, but complete WTP, equipped with package cooling towers to simplify and speed installation.

The plant design anticipated a future expansion.

- Indirect cooling circuit 1600 mc/h

- Direct cooling circuit 1300 mc/h

- Another good reference for Dan-Filters in the vietnamese market

Simec, Mexico (2015)

The Danieli supply included Casting and Rolling process cooling circuits.

- Indirect cooling circuit 6700 mc/h

- Direct cooling circuit 1800 mc/h

The DanDredge process removes the scale continuously, making it a suitable design for heavy-duty application, and its maintenance requirements are simplified.

Danieli is always one step ahaead with new and alternative solutions to meet clients' requests.

AQS - Algerian Qatary Steel, Algeria (2015)

- Indirect cooling circuit 3120 + 14270 mc/h

- Direct cooling circuit 5300 +1060 mc/h

A large and significant project that demonstrates the Danieli expertise in project management.

Gerdau Sipar, Argentina (2014)

- Indirect cooling circuit 3400 mc/h

- Direct cooling circuit 380 mc/h

ABS - Clean Heat Recovery Plant, Italy (2014)

For this purpose, Danieli Environment has developed the CHR™ - Clean Heat Recovery system to transform EAF (Electric Arc Furnace) hot fumes into electric energy.

It is well known that EAFs lose a huge volume of thermal energy through the primary fumes. This is an interesting energy source, especially if compared with renewable energies.

Our system combines Hot Water cooling and ORC (Organic Rankine Cycle) technology to produce electric energy and recover waste heat from the EAF, with a consequent savings of fuel and reduction of green-house gas emissions.

The first CHR™ plant was installed in 2014 at cciaierie Bertoli Safau S.p.A., the Danieli Group's steelmaking company in Udine, Italy.

General Holding Corporation, UAE (2008)

Sea-water Reverse-Osmosis Plant for Make-Up Water Production with a Capacity of 1600 mc/h

- Indirect cooling circuit 14000 + 9120 mc/h

- Direct cooling circuit 1275 +640 mc/h

Desalinated sea-water is the primary water source for all types of water required within the steel complex: make-up water, demineralized water, portable water, etc.

Danieli designed and manufactured all the individual treatment units: primary water production, direct and indirect cooling circuits, demineralization plant for DRI and discharge water treatment.